12. Hoisting

12. HOISTING

Heavy materials handled with cranes and hoisting equipment is an important part of

work at a shipyard. The best way to prevent any accidents while hoisting is to get to

know the right lifting methods and the right use of the lifting equipment. Hoisting operations

can be performed only by persons who have received adequate training for the

job.

Inspection of hoisting equipment

Before using any lifting equipment or lifting accessories the hoisting operator must

make sure that it is intact, certified and approved for use and inspected. Lifting equipment

must also have the maximum allowable load marked. Lifting equipment manufactured

after 1994 must carry CE marking.

Do not overload or use the lifting equipment in an incorrect manner. Overloading may

cause unseen defects in the lifting equipment that may later lead to an accident.

If you think there has been any overloading or any possible damage to the equipment,

report it to your supervisor. It is not allowed to operate the equipment until it has been

inspected.

Avoid maximum loads in freezing temperatures. In freezing conditions, steel is brittle

and weaker than at normal temperatures. Low temperatures can create a greater risk

of equipment damage or breakage.

Do not use the lifting equipment if you notice that there are defects or that it has not

been inspected. Return it and report the defects or faults to your supervisor. Overloads

and faults must be reported immediately.

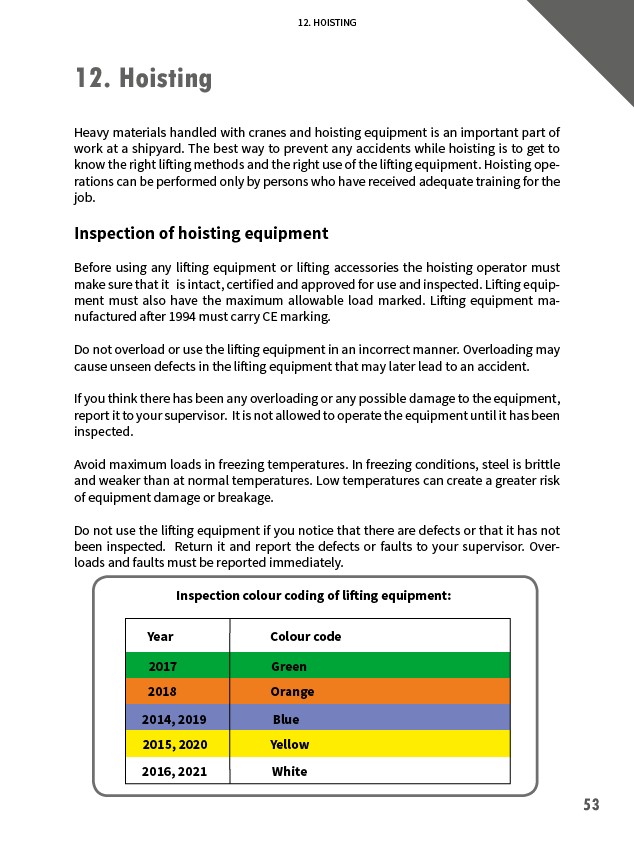

Inspection colour coding of lifting equipment:

Y e a r Colour code

2017 Green

2018 Orange

2014, 2019 Blue

2015, 2020 Yellow

2016, 2021 White

53