10. PERSONAL PROTECTIVE EQUIPMENT

Use a gas respirator if the impurities in the air are gaseous (spray painting and

washing with solvents). Use always a combined filter if the gases contain particles, e.g.

when spray painting. Choose the filter based on the required protection class and the

gas to be filtered. In spaces with a risk of explosion you must use a respirator with an

explosion proof exhaust system. All protective equipment that can be used in spaces

with a risk of explosion carry an “Ex” marking. When the oxygen content in the air gets

reduced, use always respiratory protective equipment with fresh air supply.

When working in a space with an explosion risk, it is necessary to use a respirator with

an explosion proof exhaust system (with an Ex marking).

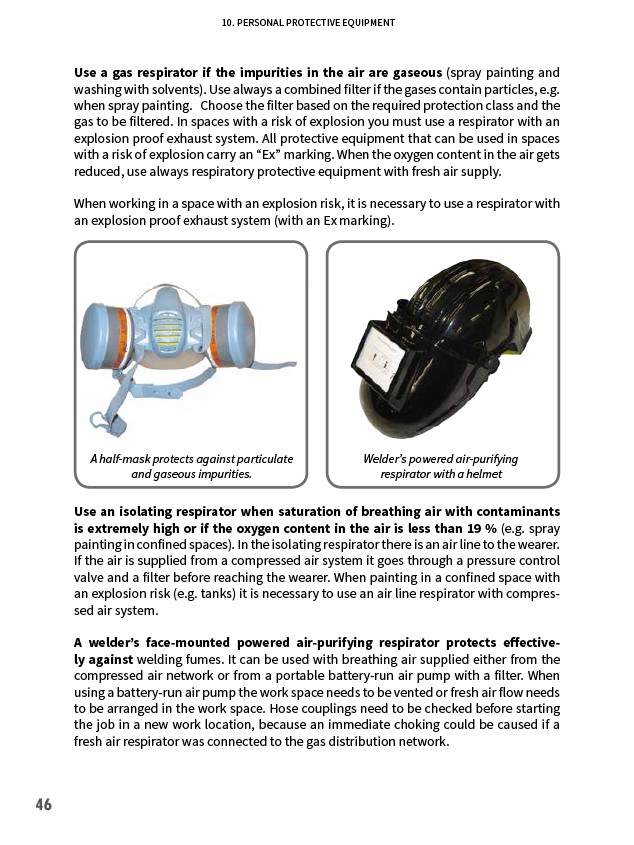

A half-mask protects against particulate

and gaseous impurities.

Welder’s powered air-purifying

respirator with a helmet

Use an isolating respirator when saturation of breathing air with contaminants

is extremely high or if the oxygen content in the air is less than 19 % (e.g. spray

painting in confined spaces). In the isolating respirator there is an air line to the wearer.

If the air is supplied from a compressed air system it goes through a pressure control

valve and a filter before reaching the wearer. When painting in a confined space with

an explosion risk (e.g. tanks) it is necessary to use an air line respirator with compressed

air system.

A welder’s face-mounted powered air-purifying respirator protects effectively

against welding fumes. It can be used with breathing air supplied either from the

compressed air network or from a portable battery-run air pump with a filter. When

using a battery-run air pump the work space needs to be vented or fresh air flow needs

to be arranged in the work space. Hose couplings need to be checked before starting

the job in a new work location, because an immediate choking could be caused if a

fresh air respirator was connected to the gas distribution network.

46